HEGGEMANN Automotive: Everything from a single source

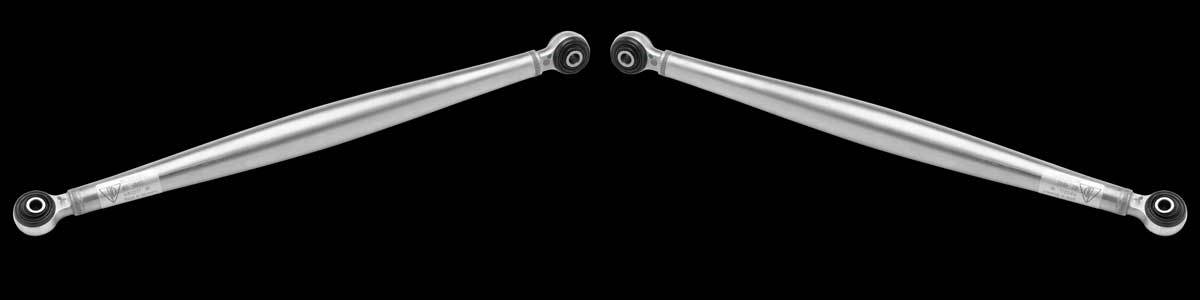

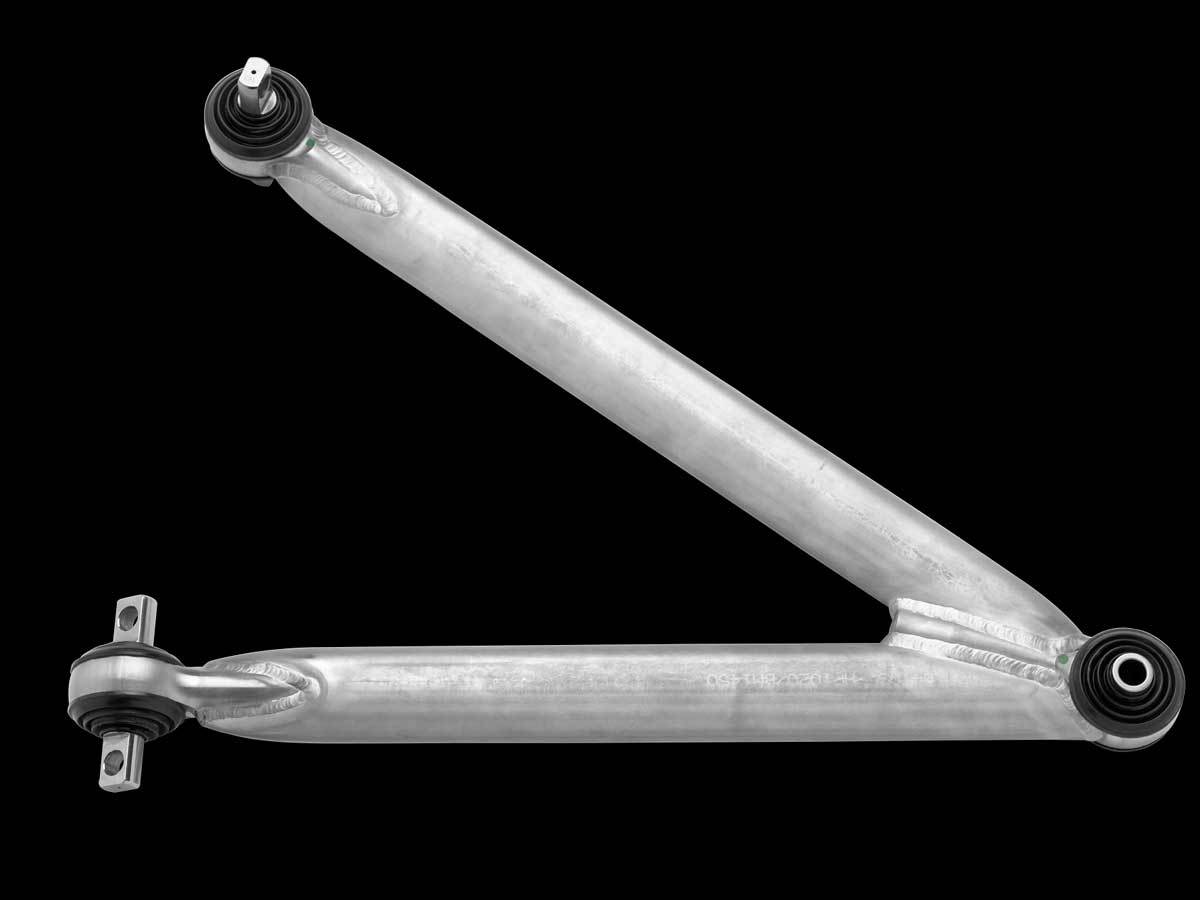

Today, in addition to cost-efficient production options, the automotive sector also offers high innovation and development potential. HEGGEMANN offers all this from a single source, from pre-development through prototype construction to pilot production and series production. At HEGGEMANN, proven processes such as FMEA, APQP and PPAP are used to optimize all the process steps involved, thus reducing the costs of series production to a minimum and meeting the highest quality requirements. Our competencies range from the development and production of sheet metal and welded assemblies to complete chassis.

Fuel systems

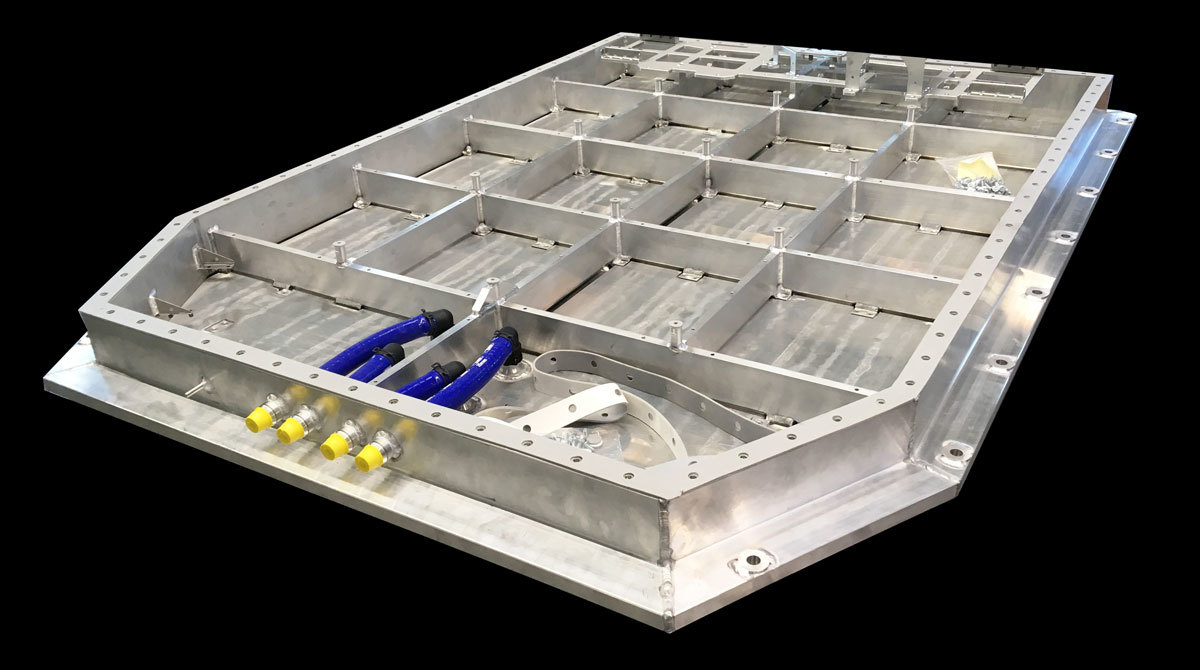

In our own tank development department, we are able to manufacture metallic prototype fulesystems for test- and pre-series vehicles with all requirements within a very short time. Furthermore, we are able to develop and manufacture metallic tanks for serial vehicles with all associated design validation plans up to a quantity to 5.000 pcs. per year.

Pre Serial

Due to its rapid implementation competence and its own toolshop, HEGGEMANN is able to produce complex robot or manually welded assemblies such as IP beams or subframes within just a few weeks.

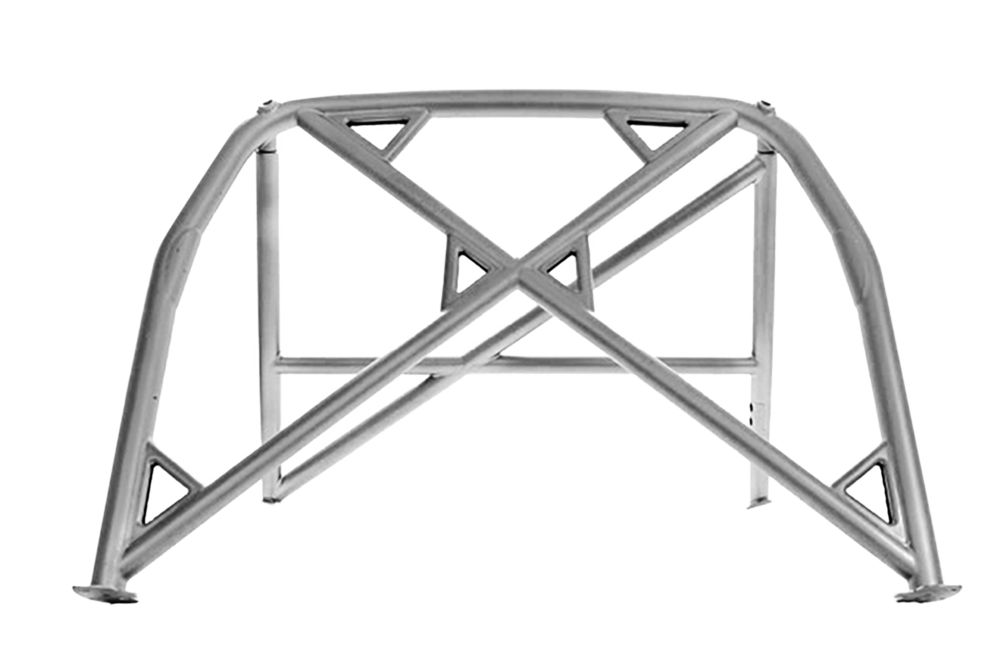

Titanium Roll Cage

Based on many years of experience in the aerospace industry and the associated processing of titanium, HEGGEMANN has specialised in the cost-effective and efficient manufacture of titanium roll cages in large quantities. Our aerospace welders are able to weld titanium without a chamber thanks to specially developed forming devices.

Picture: Porsche GT2RS

Picture: Battery box Benteler and/or water separator

Solution for future mobility

HEGGEMANN develops and manufactures forward-looking technologies for future mobility. Whether it's battery trays for electric vehicles or water separators for fuel cells — with HEGGEMANN you always get the right solution.

Small Serial Production for High Performance Cars

Aside from cost-effective production possibilities, what counts nowadays in the automotive sector, is a high potential regarding innovations and developments. HEGGEMANN offers this all from one source, including the preliminary development, the construction of prototypes, as well as pilot series and series production. At HEGGEMANN, proven processes such as FMEA, APQP ans PPAP are employed in order to optimise all processing steps involved, thus keeping the costs of series production to a minimum, while meeting highest quality demands. Our capabilities range from the development and production of sheet metal- and welded components to complete chassis.